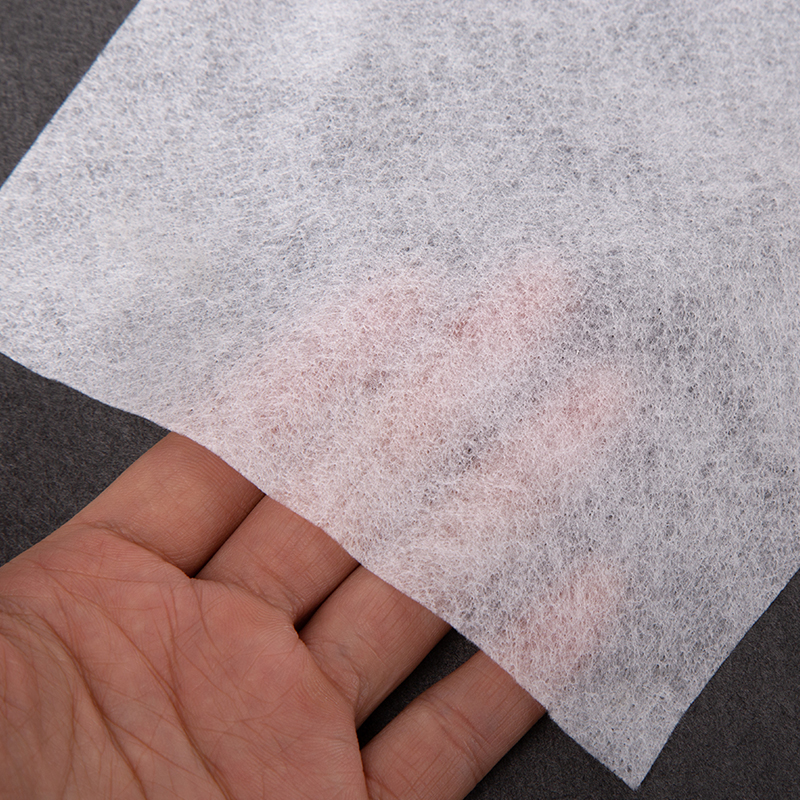

Nonwoven fabrics have revolutionized the textile industry, offering a versatile and cost-effective alternative to traditional woven and knitted fabrics. These materials are produced directly from fibers, without the need for spinning or weaving, resulting in a wide range of properties and applications.

How are Nonwoven Fabrics Made?

Nonwoven fabrics are created through a series of processes that involve:

Fiber formation: Fibers, either natural or synthetic, are formed into a web.

Bonding: The fibers are then bonded together using mechanical, thermal, or chemical methods.

Finishing: The fabric may undergo additional finishing processes such as calendering, embossing, or coating to enhance its properties.

Types of Nonwoven Fabrics

There are numerous types of nonwoven fabrics, each with its own unique characteristics and applications. Some of the most common types include:

Spunbond nonwovens: Made from continuous filaments that are extruded, stretched, and laid onto a moving belt. These fabrics are strong, durable, and often used in applications such as geotextiles, medical gowns, and filtration.

Meltblown nonwovens: Produced by extruding a polymer through fine holes to create extremely fine fibers. These fabrics are lightweight, highly absorbent, and often used in filters, masks, and hygiene products.

SMS nonwovens: A combination of spunbond, meltblown, and spunbond layers. SMS fabrics offer a balance of strength, softness, and barrier properties, making them ideal for medical gowns, diapers, and wipes.

Needle-punched nonwovens: Created by mechanically punching needles through a web of fibers to create entanglement and bonding. These fabrics are strong, durable, and often used in upholstery, automotive interiors, and geotextiles.

Spunlace nonwovens: Produced by using high-pressure jets of water to entangle fibers and create a strong, soft fabric. Spunlace nonwovens are commonly used in wipes, medical dressings, and interlinings.

Bonded nonwovens: Created by using heat, chemicals, or adhesives to bond fibers together. These fabrics can be customized with various properties to meet specific application requirements.

Coated nonwovens: Nonwoven fabrics that have been coated with a polymer or other substance to improve their properties, such as water resistance, flame retardancy, or printability.

Laminated nonwovens: Created by bonding two or more layers of nonwoven fabric or a nonwoven fabric and a film together. Laminated nonwovens offer a combination of properties, such as strength, barrier protection, and aesthetics.

Applications of Nonwoven Fabrics

Nonwoven fabrics have a wide range of applications across various industries, including:

Medical: Surgical gowns, masks, wound dressings, and diapers.

Hygiene: Wipes, feminine hygiene products, and adult incontinence products.

Automotive: Interior components, filtration, and insulation.

Geotextiles: Soil stabilization, erosion control, and drainage.

Agriculture: Crop covers, seed blankets, and geotextiles.

Industrial: Filtration, insulation, and packaging.

Conclusion

Nonwoven fabrics offer a versatile and sustainable solution for a wide range of applications. By understanding the different types of nonwoven fabrics and their unique properties, you can select the most suitable material for your specific needs.

Post time: Jul-31-2024