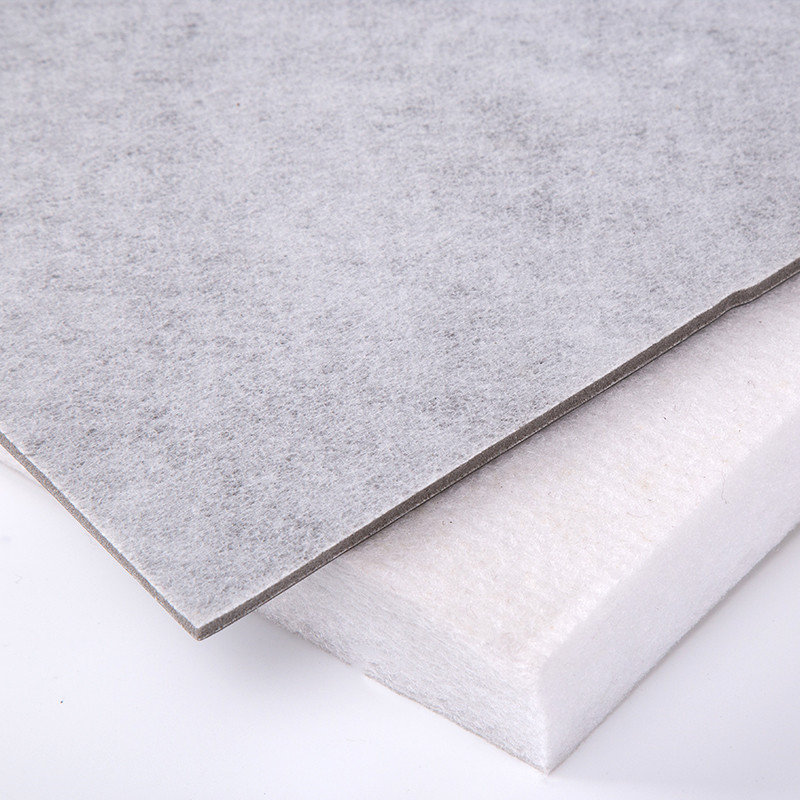

Customized Sized Spunlace Nonwoven Fabric

Product Description

Sizing is a process used to add stiffness, strength, or other desired properties to fabrics. In the case of spunlace fabric, which is produced by entangling fibers together through high-pressure water jets, sizing can be applied to enhance specific characteristics of the fabric. Sizing agents applied to spunlace fabric can improve its strength, durability, printability, softness, absorbency, and other desired properties. The sizing agent is typically applied to the fabric during the manufacturing process or as a finishing treatment.

Use of sized spunlace

Improved strength and durability:

Sizing agents can increase the tensile strength and tear resistance of the fabric, making it more durable and better suited for demanding applications.

Enhanced dimensional stability:

Sizing can improve the fabric's resistance to stretching, shrinkage, or distortion, allowing it to maintain its shape and size better over time.

Printability:

Sized spunlace fabric can have improved ink absorption and retention properties, making it suitable for printing applications. The sizing agent can help the fabric hold colors and designs more effectively, resulting in sharper and more vibrant prints.

Softness and hand feel:

Sizing agents can be used to impart or enhance softness, smoothness, or a specific texture to the spunlace fabric. This can improve the fabric's comfort and tactile characteristics, making it more appealing for applications such as wipes, facial tissues, or clothing.

Absorbency management:

Sizing agents can modify the surface properties of the fabric to control its absorbency. This can be useful in applications where precise liquid management is required, such as in medical or personal care products.

Surface modifications:

Sized spunlace fabric can also be treated to add specific functionalities, such as antimicrobial properties, flame resistance, or water repellency. These modifications can expand the range of applications for the fabric.